Reverse logistics is a relatively new term that is used to describe the process of returning goods and materials back to their original point of manufacture or distribution. It is also sometimes referred to as returns management.

However, if we consider the reverse meaning of the word logistics, which is the “science of planning and carrying out the transportation and storage of goods and materials,” then reverse logistics would be the science of returning goods and materials back to their original point of manufacture or distribution.

What Is Reverse Logistics?

Reverse logistics is a type of supply chain management that deals with the return of goods and materials back to their original point of manufacture or distribution. The term “reverse logistics” was first coined by Dr. reverse in a study he conducted in the early 1990s.

Types of Reverse Logistics

Green reverse logistics:

Reverse logistics are a great way to make sure that your products don’t end up in landfills after they’ve been used. The process starts with the returned product, which undergoes an environmentally-friendly repair or recycling procedure before being sold again!

Return reverse logistics:

This type of reverse logistics deals with the return of goods that were sold but not used. Return reverse logistics is a great way to keep products from going to waste and ending up in landfills!

Recall reverse logistics:

Recall processing is a type of reverse logistics that deals with the return of defective or dangerous products. Returned products are either repaired or disposed of in an environmentally-safe manner.

When Is Reverse Logistics Used?

Reverse logistics are used when products or materials need to be returned back to their original point of manufacture or distribution. This can happen for a variety of reasons, such as:

- The product is defective

- The product was sold but not used

- The product needs to be recalled

- The product needs to be disposed of in an environmentally-safe manner

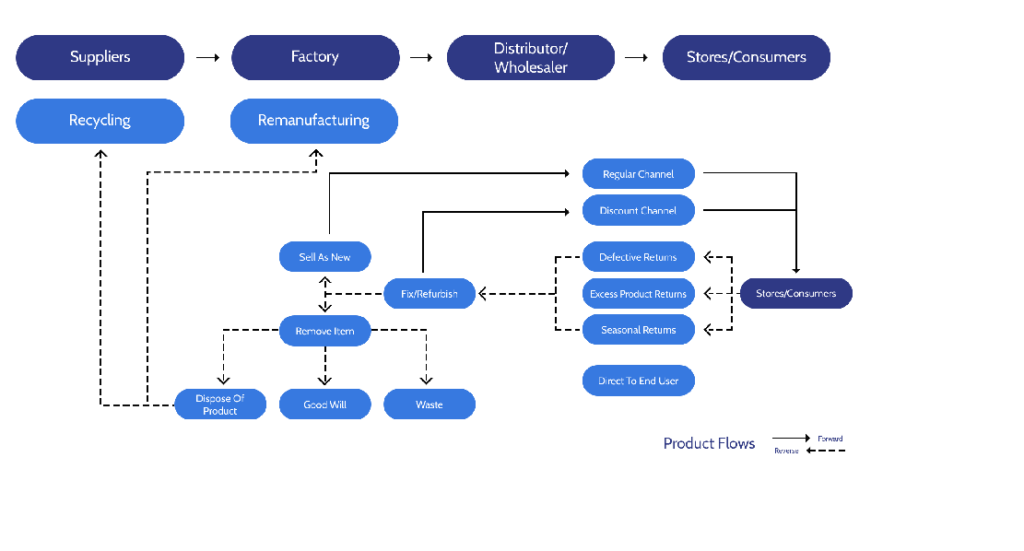

Reverse vs Traditional Logistics

Reverse logistics is the process of managing the return of goods and materials back to their original manufacturers or suppliers. It includes all activities associated with returns, including product repair, replacement, and refund processing. Traditional logistics, on the other hand, is focused on getting products from suppliers to customers in an efficient and cost-effective manner.

Forward and Reverse Logistics Process

How Does Reverse Logistics Work?

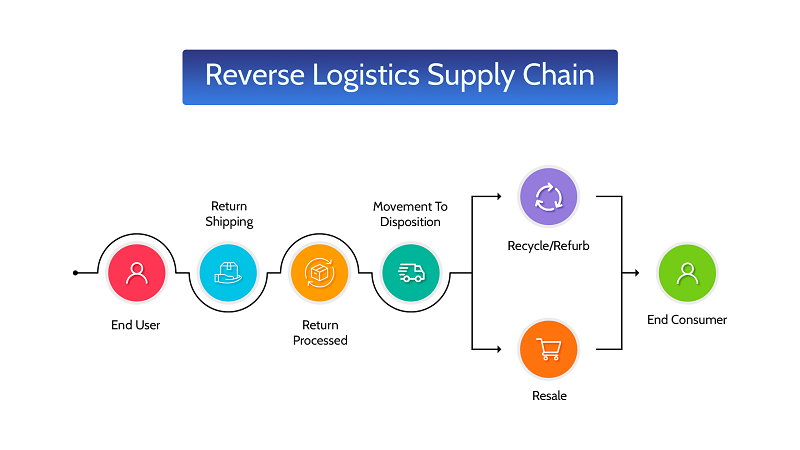

Reverse logistics typically involve four steps:

1. Pick-up: The first step in reverse logistics is to pick up the product or material that needs to be returned. This can be done by the company that manufactured the product, by the retailer who sold the product, or by a third-party reverse logistics provider.

2. Transportation: Once the product has been picked up, it needs to be transported back to the original point of manufacture or distribution. This can be done via truck, train, plane, or ship.

3. Processing: The next step in reverse logistics is to process the return. This typically involves inspecting the product, repairing it if necessary, and then either restocking it or recycling it.

4. Return: The final step in reverse logistics is to return the product or material back to the original point of manufacture or distribution. Once the product has been processed, it will be shipped back to the company that manufactured it or the retailer who sold it.

Reverse logistics can be a complex and time-consuming process, but it is an important part of supply chain management. By using reverse logistics, companies can reduce waste, save money, and improve customer satisfaction.

Importance of Reverse Logistics to Your Business

There are a number of reasons why reverse logistics is important to your business.

- Reverse logistics can help you save money. Returns management is often expensive, and by using reverse logistics, you can reduce the cost of returns.

- It can help you improve customer satisfaction. By using reverse logistics, you can make sure that your customers are happy with their purchase and that they received the product they expected.

- Reverse logistics can help you reduce waste. By using reverse logistics, you can make sure that products are recycled or disposed of in an environmentally-safe manner.

Benefits of Optimized Reverse Logistics

There are a number of benefits that can be gained by optimizing reverse logistics.

Some of the benefits of optimized reverse logistics include:

- Improved customer satisfaction

- Reduced cost of returns

- Improved inventory management

- Reduced waste

- Improved environmental sustainability

7 Strategies to Optimize Reverse Logistics

There are a number of strategies that can be used to optimize reverse logistics.

Some of the strategies that can be used to optimize reverse logistics include:

1. Use Returns Management Software

Returns management software can help you automate the reverse logistics process and make it more efficient. By using returns management software, you can track returns, process refunds, and print return labels.

2. Educate Your Employees

It is important to educate your employees about reverse logistics. By educating your employees, you can make sure that they are aware of the reverse logistics process and how it works.

3. Implement a Returns Policy

A returns policy can help you manage returns and improve customer satisfaction. By implementing a returns policy, you can make sure that customers are aware of your return policy and that they understand the process.

4. Use reverse logistics providers

Reverse logistics providers can help you manage the reverse logistics process. By using reverse logistics providers, you can outsource the reverse logistics process and focus on other aspects of your business.

5. Use barcodes and RFID tags

Barcodes and RFID tags can help you track products and make the reverse logistics process more efficient. By using barcodes and RFID tags, you can track product returns and ensure that products are returned to the correct location.

6. Implement quality control measures

Quality control measures can help you reduce the number of returns. By implementing quality control measures, you can make sure that products are of high quality and that they meet customer expectations.

7. Use reverse logistics analytics

Reverse logistics analytics can help you understand the reverse logistics process and make it more efficient. By using reverse logistics analytics, you can track return rates, identify trends, and improve the reverse logistics process.

What Are the Five Rs of Reverse Logistics?

The five Rs of reverse logistics are:

1. Recycle – Make sure that products are recycled or disposed of in an environmentally-friendly manner.

2. Refurbish – Refurbish products that can be used again.

3. Resell – Resell products that are in good condition.

4. Dispose of – Dispose of products that cannot be used again.

5. Repair – Repair products that are broken or damaged.

The Future of Reverse Logistics

The reverse logistics industry is expected to grow in the coming years. This growth is being driven by the increase in e-commerce, the rise of omnichannel retail, and the growth of the sharing economy.

As the reverse logistics industry grows, we can expect to see more innovation in the field of reverse logistics. We can also expect to see more reverse logistics providers and reverse logistics software.

The future of reverse logistics is exciting and it will be interesting to see how the industry develops in the coming years.